Curing Technology Applications in metal printing

Traditional tinplate printing is divided into three kinds of curing:

Thermal Curing

Traditional tinplate printing is divided into three types of curing:

Thermal Curing

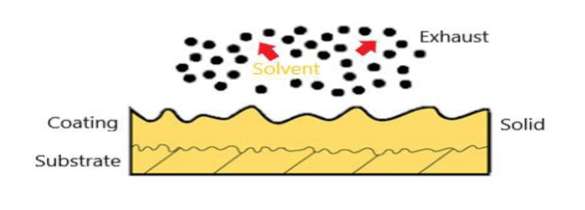

It is process of a liquid material or solid powder forms a film by hot melting under high temperature.

Thermoset coatings/inks/paints/glue components

Solvents, Resins, Additives

Characteristic:

1)Curing requires high temperatures, slow speeds, and large amounts of volatiles (water-based or oil-based solvents) are produced during the curing process.

2)It takes up a lot of space in the workshop.

3)Huge amounts of V.O.C emissions

4)The base material may have uncertain hazards.

5)Tons of thermal energy is required.

Electron Beam Curing

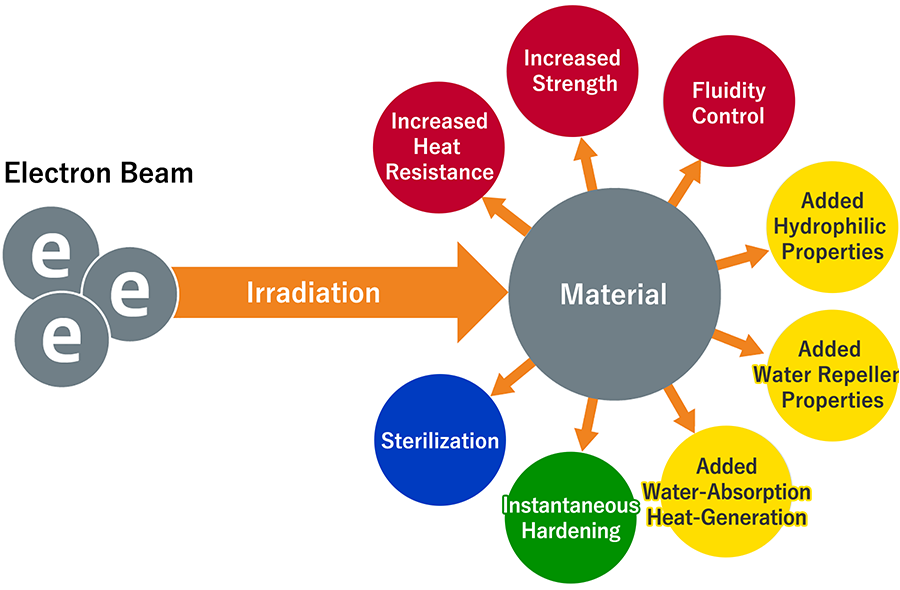

The process of cross-linking and filming is generated by activating the material through the stock force of radiating electrons.

Electron Beam ink

Pigments/binders/auxiliaries

Characteristic:

1)Fast and energy-efficient curing process (5% of UV curing)

2)100% complete curing, no post-curing, no contamination, and sterilization effect at the same time, especially suitable for food packaging room temperature curing.

The shrinkage and distortion are relatively strong UV penetration, the curing dose utilization rate is high, the conversion rate can reach 95%, and the production efficiency is

UV Curing

The liquid material is crosslinked and solidified into a film under the action of UV photons.

UV curing coating/ink/glue components.

Curing agents (monomers, oligomers), photo-initiator ,Additive

Characteristic

1)Cold working with in-line process, instant curing at room temperature

2)Modular, simple curing tunnel, low power consumption

3)No solvent volatilization, protective effect on some sensitive substrates

UV Curing Lamps

Output Graph of working time for Arc Lamp-Microwave Lamp-UVLED

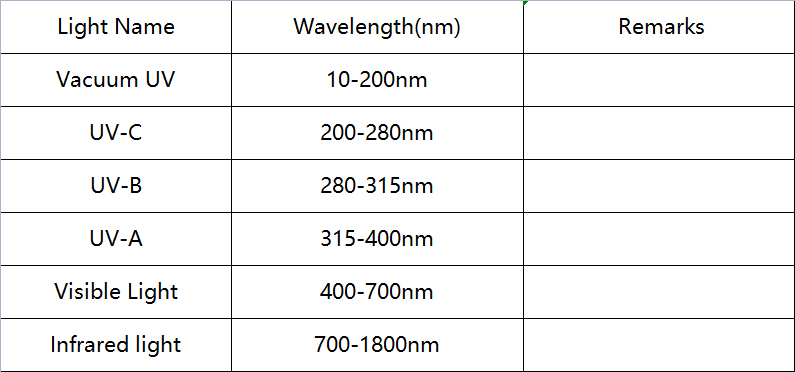

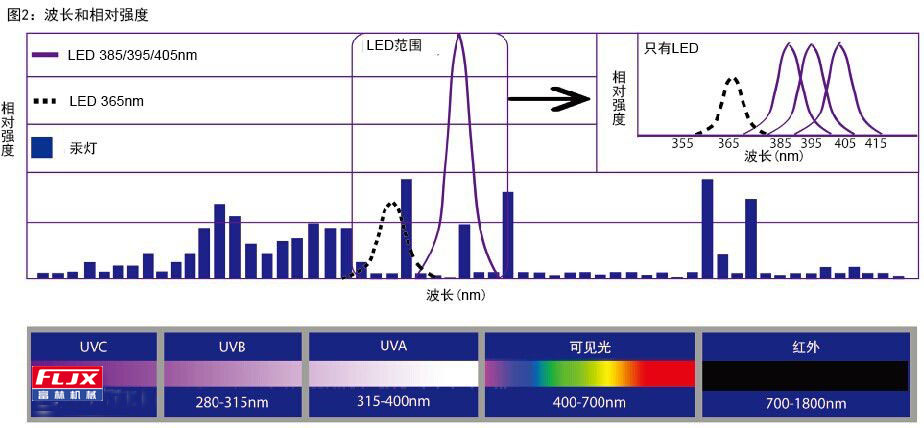

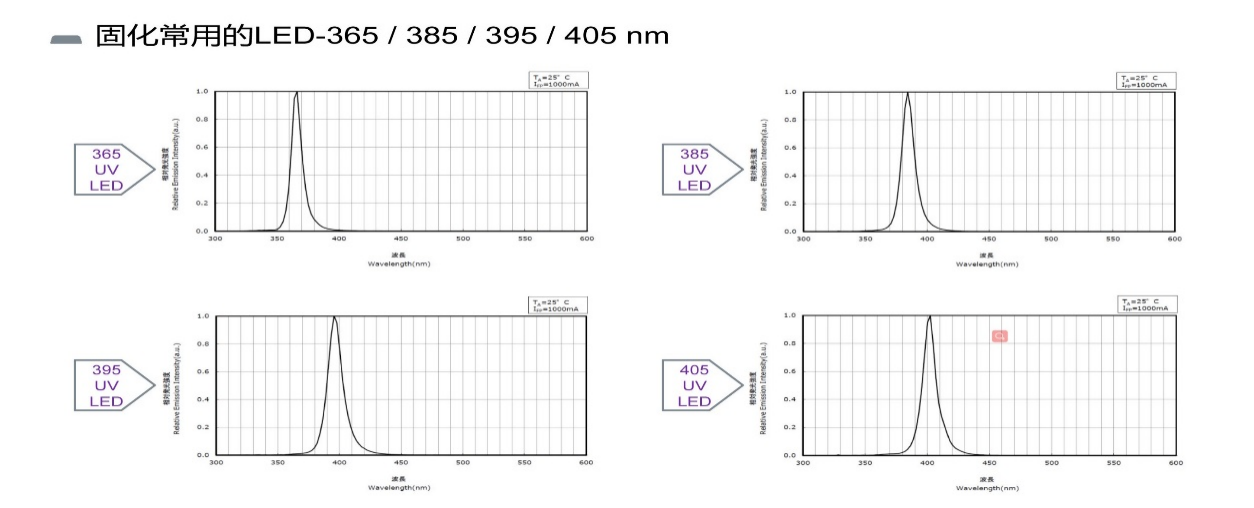

UVLED Wavelength Type

UVLED Curing Wavelength

UVLED Curing Principle

The photo-initiator absorbs the radiation energy of ultraviolet light and splits into free radicals, causing the prepolymer to polymerize, cross-link branch reaction, solidify into a three-dimensional network polymer in a very short time, and obtain a hardened film, which is essentially chemical drying by forming chemical bonds.

1)Interaction between light and initiator, which may include the absorption of light and the interaction between photo-initiator.

2)The photo-initiator molecules are rearranged to form free radical intermediates.

3)Interaction between light and initiator, which may include the absorption of light and the interaction between photo-initiator.

4)The photo-initiator molecules are rearranged to form free radical intermediates.

UV Curing Machine

UV light curing has been used at home and abroad for more than ten years, and there are some obvious defects:

1. Mercury lamp UV light intensity attenuation is fast (1500H)

2. The surface temperature of the iron sheet rises (it is necessary to add a cooling system at the rear of the UV machine, or install heat insulation glass but lose about 15% of the light intensity)

3. The industry has been committed to improving defects such as poor deep processing performance, but it has been difficult to make a big breakthrough due to the limitations of the original hardware.

UVLED Curing

UVLED curing is a kind of UV curing, which uses UV LED light source to cure UVLED ink, UV coating, etc., and the equipment has also undergone a process of continuous research and development and improvement.

In 2016, the advent of the UVLED multi-color system of an Italian company brought revolutionary changes to the UV curing industry. It has the characteristics of constant light intensity, excellent temperature control, portable and environmentally friendly, which has promoted the quality improvement and energy saving and consumption reduction of the UV curing process.

Fulin Machinery, as a professional manufacturer that has been committed to the R&D and promotion of tinplate UV curing technology for a long time, Our factory has cooperated with well-known domestic companies to develop UVLED since 2015, and has made a breakthrough in UVLED curing technology in 2018, which is helping the metal printing industry to move towards to eco-friendly, energy-saving and environmental protection. Among them, a 4-color UVLED curing equipment installed for COFCO Packaging Company in October of that year is representative, It only took 1 month to install and trail operation successfully for full UVLED curing line, due to the good curing condition, the machine performance meets customer requirements and the overall operation is quite normal. After 5 years of craft precipitation and technological innovation, our UVLED line has been successfully installed and used at domestic and overseas up to 90 lines.

Overall, the system has the following four main features:

1)Professional power supply performance. The system provides a clean, pure DC power supply with a ripple current of 0.4%. The startup process takes soft start, no overshoot current, effectively ensure the life of UV LED lamps. The fast response start function enables the timely start after suspending output and eliminate the possibility of missing curing products. High-precision digital control output ensures that the light intensity of each part of the whole lamp is highly consistent.

2)Comprehensive information management. Monitor the current, voltage, temperature, chip damage of the lamp board in real time, and through the signal Processing feedback is fed back to the HMI to guide users to resolve issues when anomalies are discovered. The Built-in professional algorithm system can analyze the cooling capacity, which will avoid condensation of UV LED water-cooled radiators.

3)The output interface is flexible and saves energy consumption. Small-lot printing does not need to turn on the full light, this system supports 24 segment output, and the printing machine automatically switches according to the metal sheet size, no need to set every time.

4)High reliability and good electrical indicators. This system adopts industrial-grade, automotive-grade electronic devices and excellent cooling system can effectively guarantee the power supply life. Three-phase input balanced, power efficiency above 94%, can proper functioning in high temperature at 50°C, the electrical safety characteristics reach the EU technical indicators, like EMC, CE and other international standards.

5)The water-cooling UVLED is a cold light source, and the heat comes from the chip itself, So the cooling of the chip is crucial. Presently. In addition, the UVLED Encapsulation can be changed according to different application environments, and the power can also be adjusted accordingly.

Through comprehensive analysis and statistics of comprehensive power consumption, equipment operation, a four-color UVLED Curing line is expected to save about $45,000~$55,000 per year compared with a four-color UV Curing printing line.

The application of UV LED technology in the metal plate printing industry is getting closer and closer, and the industry participant is also thinking about how to approach to the new trend of green energy conservation and the challenges of new technologies.

Tel: +86 757 22620036

Tel: +86 757 22620036 Fax: +86 757 2262 8636

Fax: +86 757 2262 8636 E-mail: Y072@163.com(中文)

E-mail: Y072@163.com(中文) Tel: Address: 120 Daliang Liangle Road, Shunde District, Foshan City, Guangdong Province -528300

Tel: Address: 120 Daliang Liangle Road, Shunde District, Foshan City, Guangdong Province -528300