佛山林富机械制造有限公司

Foshan Linfu Machinery Manufacturing Co., Ltd

E-mail:Y072@163.com

salesfulinmachinery@outlook.com

|

Description |

Specification |

|

Max Inspection Width (W*L) |

1120mm ×955mm |

|

Min Inspection Width (W*L) |

712mm × 510mm |

|

Max Convey Speed(m/min) |

120m/min |

|

Thickness of the inspection sheet(mm) |

0.16mm~0.4mm |

|

Max Speed Inspection(sheet/min or m/h) |

100 sheet/min 6000sheet/h |

|

Image capture resolution(L*W)(mm) |

Printing Side:0.13mm×0.1mm Back Side:0.13mm×0.1mm |

|

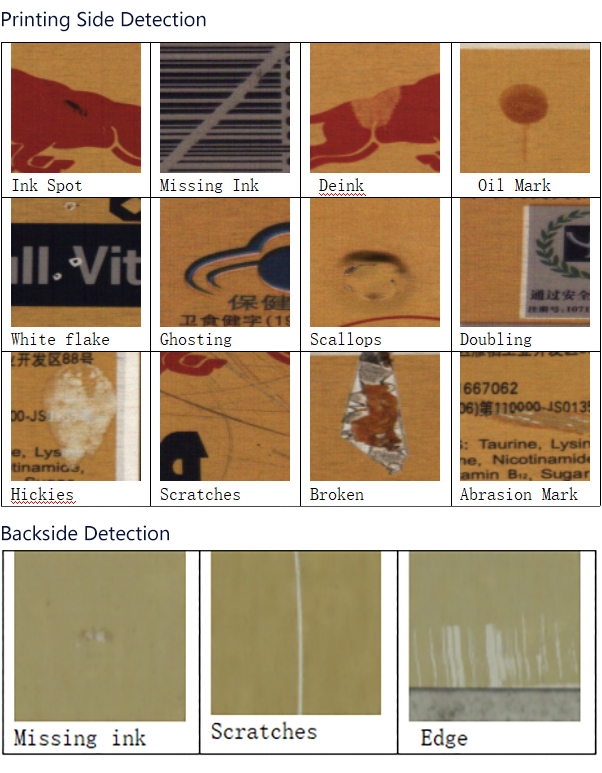

Minimum Point Defect Size(mm2)(ink droping、missing ink Dirt etc. |

Under High Contrast 0.1mm2 Under Low Contrast 0.15mm2 |

|

Minimum size of Linear Defect (streaks etc.) |

Under High Contrast Width≧0.1mm Length≧5mm Under Low Contrast Width≧0.15mm Length≧5mm |

|

Color difference detection |

Solid Primer Color△E≧2,Others△E≧3 |

|

Out of register (mm) |

Sheet Width Direction: ±0.13mm;Motion Direction: ±0.1mm |

|

Working Sections Allocation |

Front 1working section with 2 cameras Back 1 working section with 2 cameras |

|

Alarming ways |

Acousto-optic |

|

Qualified Sheets Receiving |

Stacked |

|

Defective Sheets Receiving |

Stacked |

|

Maximum Stacking Weight for Feeding |

2T |

|

Maximum Stacking Weight for Qualified Sheets |

2T |

|

Maximum Stacking Weight for Defective Sheets |

2T |

|

Measurement(L*W*H) mm |

14200mm×1800mm×1700mm |

|

Weight |

10T |

|

Power |

35KW |

Whether you have technical questions to consult with, or have any opinions or suggestions, we are looking forward to receiving your message

You can find us through phone, email, or the message system here

Tel: +86 757 22620036

Tel: +86 757 22620036

Fax: +86 757 2262 8636

Fax: +86 757 2262 8636

E-mail: Y072@163.com(中文)

E-mail: Y072@163.com(中文)

E-mail: salesfulinmachinery@outlook.com(English)

E-mail: salesfulinmachinery@outlook.com(English)

Tel: Address: 120 Daliang Liangle Road, Shunde District, Foshan City, Guangdong Province -528300

Tel: Address: 120 Daliang Liangle Road, Shunde District, Foshan City, Guangdong Province -528300